ERIKS Gasket Technology

ERIKS is a world leader with more than 75 years’ experience in the production and distribution of flange gaskets and (semi) metallic gaskets. ERIKS has the right team and the right products to meet your company’s needs.

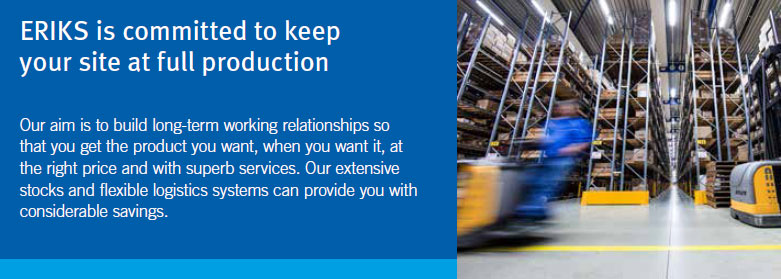

Our business incorporates numerous group companies in multiple countries around the globe. We have a dedicated local team with national stocks and the support of worldwide ERIKS network, so you can get the parts you need, when you need them. Our hallmark is quality. From product range to customer service; from design to logistics and supply systems, ERIKS is entirely focused on providing you, the customer, with excellence in all that we do.

We ensure that oil & gas exploration and drilling companies, vessel repairers, (petro)chemical plants, utility suppliers, food manufacturers, pharmaceuticals and other key industries function effectively by supplying only the best materials available on the market.

Rapid Customising

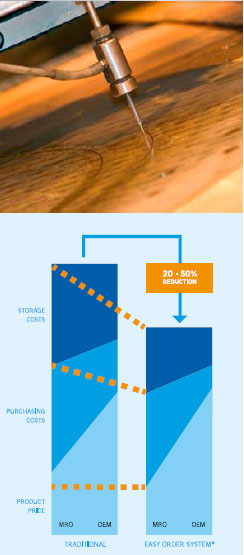

ERIKS is a dynamic company constantly developing our expertise in new fields of engineering. Components are manufactured in accordance with all relevant standards and our team of experienced engineers use an extensive range of cutting methods to craft your exact requirements. We can cut every conceivable flange gasket in-house in minutes. Precisely.

Supply chain solutions

Are you planning to reduce your procurement costs?

Do you want to reduce your Total Cost of Ownership once and for all?

Are you looking for a solid partner who can help you achieve these goals?

Then we would like to welcome you to the

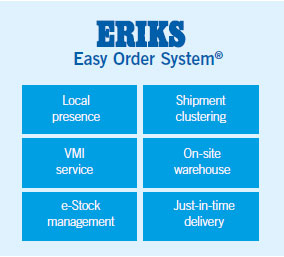

ERIKS Easy Order System®

ERIKS is more than capable of meeting your exacting requirements

A summary of our gasket product range is provided. Our sales team will be delighted to provide detailed, technical advice as to performance and suitability for specific applications.

Fibre sheet jointing

![]() High quality for general purposes

High quality for general purposes

RX PT20

High quality for general purposes

RX PT20

Excellent choice for general chemical applications

Excellent choice for general chemical applications

RX PT60

Composite PTFE gaskets

The best for applications across the whole pH-range

The best for applications across the whole pH-range

Leader GT Clipperlon 2100

Perfect solution for use in low bolt loaded constructions

Leader GT Clipperlon 2110

The high-performance all-rounder

Leader GT Clipperlon 2120

Reinforced graphite gaskets

Excellent for applications involving high sealing stresses

Excellent for applications involving high sealing stresses

RX Egraflex Tanged Graphite/ Econgraph-ti

For maximum safety requirements

Frenzelit Novaphit SSTC

The most optimised pressure/ temperature ratio

Frenzelit Novaphit MST

Spiral wound gaskets

Safe, effective seal for high temperature applications

Safe, effective seal for high temperature applications

Leader GT Style S

For flanges without a compression stop

Leader GT Style SI

Ideal SWG with radial strength to prevent blowout

Leader GT Style SR

The ultimate SWG for all flange ratings

Leader GT Style SRI